Embossing solutions

Our machines are designed to meet the highest quality standards and optimise your production process. They offer you flexibility, reliability and performance for a wide range of applications.

Technology

Experience the benefits of our cutting-edge technology and let the quality and precision of our printing solutions convince you. Contact us for more information or a personal consultation. Together we can make your printing projects a success.

At AKK, we rely on state-of-the-art machines and innovative processes to offer you customised solutions for your individual requirements.

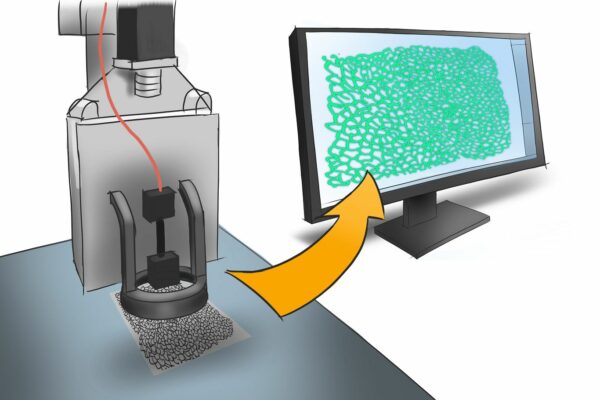

3D Scan of design

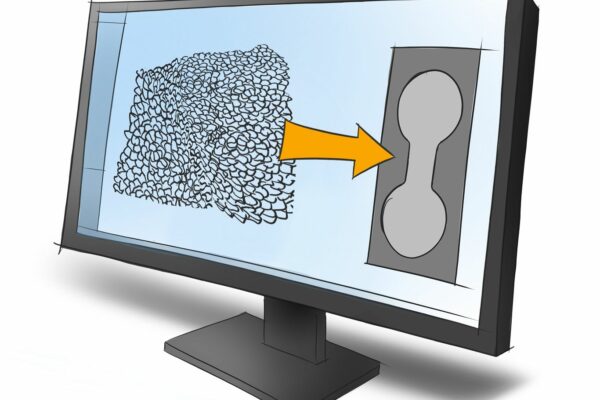

Artwork of design

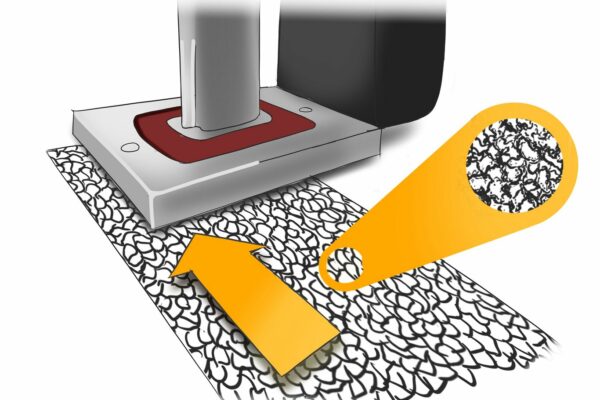

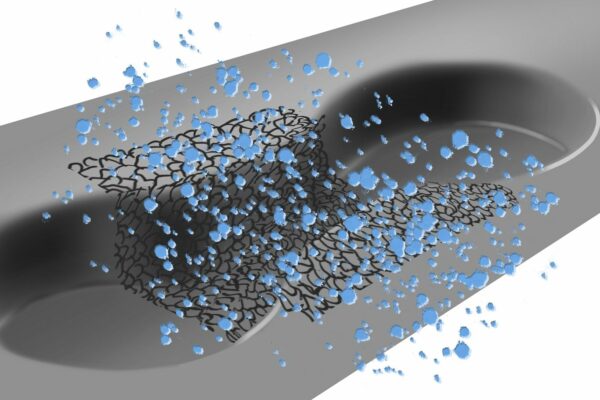

Paste print on foil

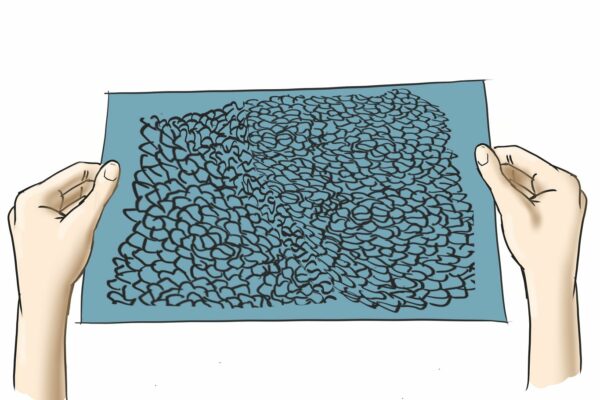

Finished foilprint

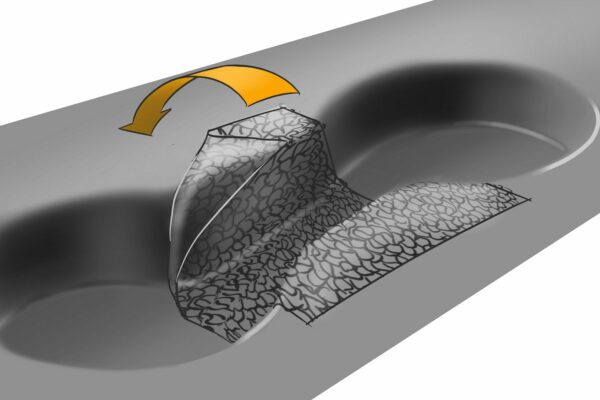

Positioning of Folie

Transfer of paste into the Mold

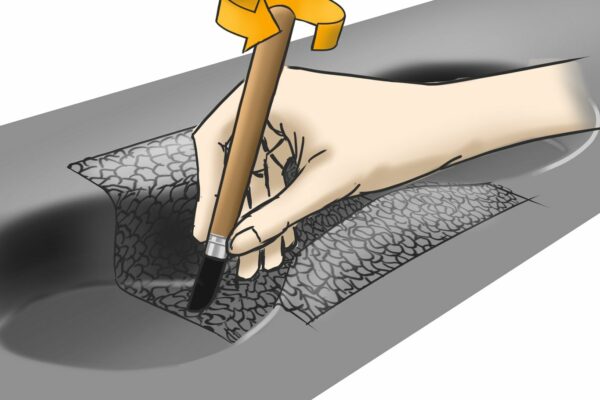

Take of the foil and etching

First of all, digital data must be created for Gravity. All our systems require TIFF data with resolutions between 1,000-1,440 dpi. The data is loaded into the machine and the film or paper to be printed is clamped. Our vacuum system ensures that there is no air under the film that could affect the print result. The paste is printed onto the film and the finished film is then positioned in the mold with the “sticky” printed side facing down. The paste is then transferred to the film using light pressure and a tool. The film is then peeled off, leaving the paste in the mold and protecting it during the etching process. This step can be repeated as often as required.

In the production of embossing plates and rollers, we print directly onto the steel and an automatic positioning system ensures that multiple etchings are possible.