Flexo EPDM solutions

Our machines are designed to meet the highest quality standards and optimise your production process. They offer you flexibility, reliability and performance for a wide range of applications.

Technology

Experience the benefits of our cutting-edge technology and let the quality and precision of our printing solutions convince you. Contact us for more information or a personal consultation. Together we can make your printing projects a success.

At AKK, we rely on state-of-the-art machines and innovative processes to offer you customised solutions for your individual requirements.

Laser Technology

Undercut

Template Plug and fit

Cantilever

Negativ Engraving

2in1

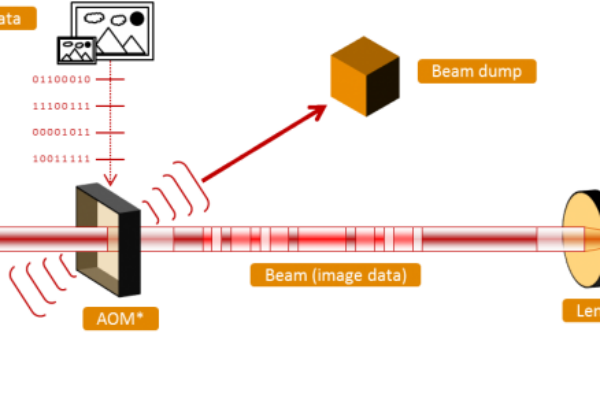

Our laser systems have the following technical applications. The laser beam passes through an AOM, which guides the beam either directly to the lens, where it focuses and then engraves the medium (sleeve, plate, roller), or into the “trap”, where the beam is absorbed. Depending on the application, the system is available with one or two laser beams. The AOM thus transfers the input files to the medium by means of pulses.

The laser power of a unit ranges between 500-750 watts for CO2 lasers and 1,000 watts for fiber lasers

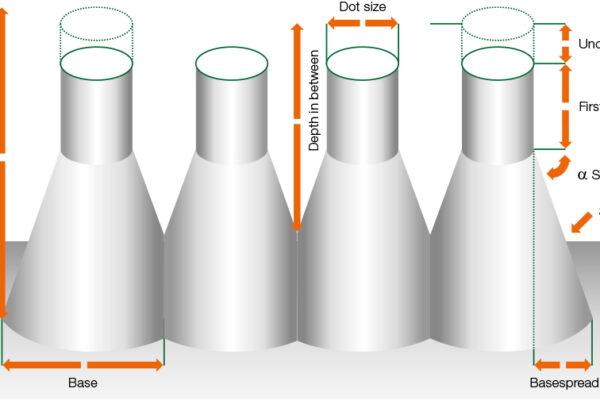

Our special AKK software makes it possible to define the best engraving curve for each application. This means that the engraving shoulder can be steeper or flatter. Furthermore, a so-called “undercut” can be engraved.

This places individual print areas below the surface of the other print areas. This is often used for flexible products such as napkin printing. With this software solution, print areas are defined (e.g. from 1-20%), which then lie linearly at different depths below the surface. The printer can now concentrate on the 100% tone, set this and, due to the higher pressure, the deeper dots touch the medium and create a fine gradient with light dots. The pressure increase can thus be influenced and optimized independently of the engraving curve setting. Our team helps with the print settings to adjust the parameters to the print medium and save these settings.

Our AKK template software enables our client to carry out the work steps intuitively. We are constantly working on optimising the processes for our customer. Customer requirements are implemented in the software according to their needs. Visualisation of the “plug and fit” from design to engraving plate, monitoring of engraving, control of water cooling are just a few of our many tools that make engraving easier and safer. Individual settings of the undercut and the engraving shoulder are worked out and saved with the customer.

The system is supplied with a magnetic cylinder or vacuum cylinder. In combination with the positioning pins, not only the assembly in the engraving unit is optimised, but also later in the printing press, as the plates are engraved directly 100% in register.

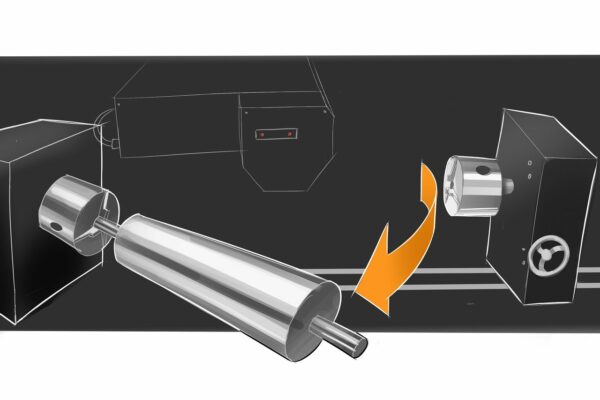

With the cantilever system, sleeves with adapters and without adapters can be changed quickly and swiftly in the machine. This is a considerable process optimisation, especially for small sleeves. If required, several sleeves can also be fitted and our software then automatically engraves the sleeves with the template plug and fit function with negative edge information in which, for example, the date, BA no. or the customer can be engraved. This will not be printed later, as it lies beneath the surface.

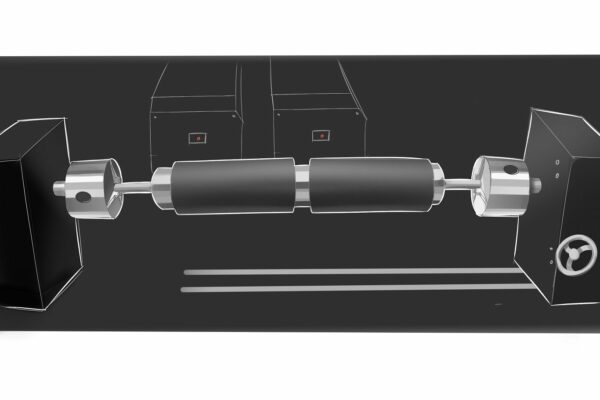

The new 2in1 function makes it possible to move the heads towards each other and thus either engrave 1 sleeve together quickly and deeply or two sleeves independently of each other. The advantage here is that the highest engraving quality can be achieved with this system. With this design principle, both lasers act as a backup; if one should fail, the system can continue engraving at 50% capacity with the same quality.